Driver board, LED Tile, Modules, Panels, Quads, etc. It’s easy to be misled into thinking they were different things but really they’re all different names for the same thing: an LED “panel” made up of a matrix of either 8×16, 16×16, or even 32×32 pixels (LED groups) with connectors for power and data. LED components can be confusing and even though the industry has been in existence for decades, the terms are not standardized across the board. Here’s a quick tutorial on all the main parts of an LED display that we’ll expand on in future posts.

Power Supplies: These convert the main power (AC) to low voltage power (DC) to power the components of the display. We use proven and reliable suppliers like Delta for our displays and have internals conformal coated to extend life and performance over time.

Controller: The controller is the engine which drives the LED Sign forward. There’s a reason auto manufacturers spend so much money and time on their engines, the engine makes a huge difference. Our engine, the new Horizon controller provides a powerful foundation for content playback, live video, communications, and all weather reliability.

LED Panels and PCB (Printed Circuit Boards): These are the modules that hold the actual LED’s that produce the light for an LED display, driven by the PCB behind them. The quality of these components is critical to a great sign that looks good, and operates well over time. Cheaper companies use off-the shelf providers overseas with no control over the materials, specifications or manufacturing processes. We have complete control over our LED’s, manufactured to our specifications, with regular testing and quality control in place.

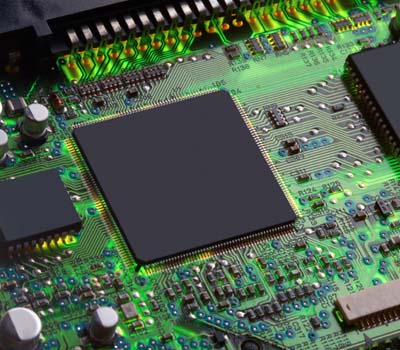

System Control Cards (Video Boards and Logic Boards): These components distribute the video signal from the controller, to the actual LED modules. During COVID a severe semiconductor supply chain was shorted and manufacturers of everything from PCs to Cars have had to scramble to get what they need. Without solid sourcing and backup plans, it’s too easy for a localized event to suddenly cause issues with the ability for a manufacturer to meet market demand. Our sourcing methods helped us minimize the effect of these events, but many other providers extended their lead times significantly from 4-6 weeks to 12 or more. Proper sourcing avoids these kinds of pitfalls.

Software: Is this a component? Most definitely! All too often we see end-users getting sub-par software developed overseas. The software is your daily interface and interaction with an LED Sign, if it’s not easy-to-use and well supported – the sign will quickly become more of a headache than a help for your organization. Our software is developed fully in-house, with both cloud-based, local, and custom solutions for any project.

Don’t accept a mediocre solution at a low price. Fight for the best combination of quality and price possible and always dig deeper. Make sure what you’re getting is what you expect and the provider can meet your needs.